is recommended for production lines up to 85 pallets/hour – according to product & pallet types

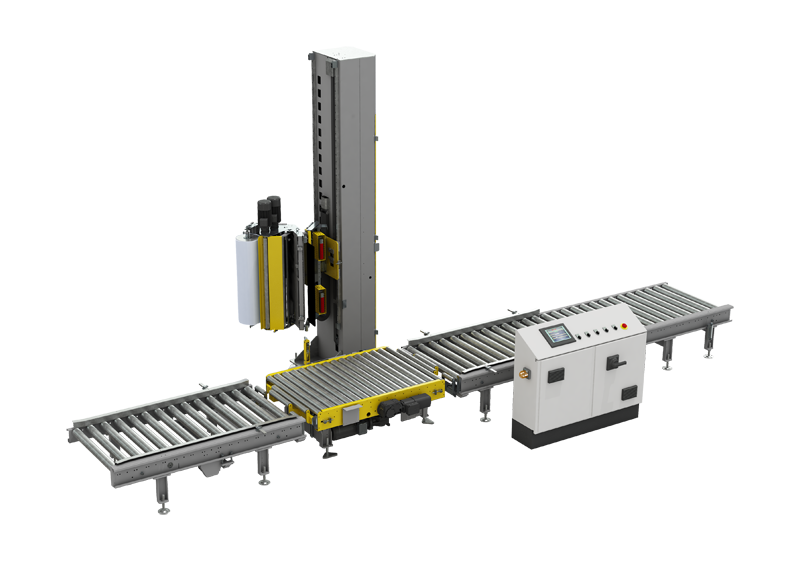

The DRAGON Beverage palletizing cell is designed for flexibility, speed and accessibility. This is accomplished by utilizing Fanuc robots to form individual packages into layers and a second, larger Fanuc robot fitted with a patented “forks gripper” to place the layers on a pallet. The DRAGON Beverage palletizer is suitable for PET, glass, or cans. The gentle robot handling of individual packages and full layers eliminates the risk of product damages and provides inherent flexibility to stack various formats (i.e. shrink, hi-cone, trays…) on multiple pallet platforms (i.e. full pallets, ½ pallets, display pallets...).

The DRAGON Beverage palletizing cell is designed to be close coupled to the end of the packaging line and is completely accessible from the floor level, thus requiring no expensive platforms and eliminates safety risks associated with working on elevated surfaces.

Equipped with operator friendly HMI and Auto-Pallet Pattern creation software, the DRAGON Beverage palletizer is designed for quick recovery after upset conditions and capable of changing to never before run formats without the need for PLC or teach pendant programming. Mechanical adjustments for format change are normally not required.

more than

1650

robotic automatic

systems Installed

3450

Laser Guide Vehicles installed

649

Employees

11

branches worldwide

Italian

Italian